Page 34 - 3D Metal Printing Spring 2017

P. 34

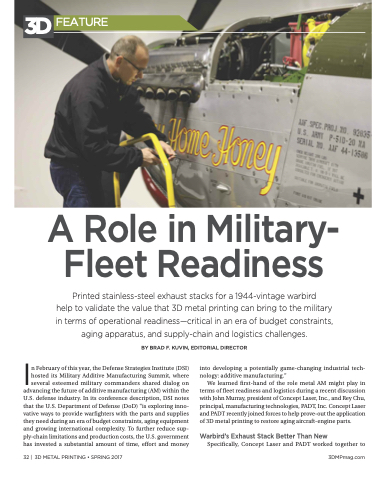

A Role in Military- Fleet Readiness

Printed stainless-steel exhaust stacks for a 1944-vintage warbird help to validate the value that 3D metal printing can bring to the military in terms of operational readiness—critical in an era of budget constraints, aging apparatus, and supply-chain and logistics challenges.

BY BRAD F. KUVIN, EDITORIAL DIRECTOR

In February of this year, the Defense Strategies Institute (DSI) hosted its Military Additive Manufacturing Summit, where several esteemed military commanders shared dialog on advancing the future of additive manufacturing (AM) within the U.S. defense industry. In its conference description, DSI notes that the U.S. Department of Defense (DoD) “is exploring inno- vative ways to provide warfighters with the parts and supplies they need during an era of budget constraints, aging equipment and growing international complexity. To further reduce sup- ply-chain limitations and production costs, the U.S. government has invested a substantial amount of time, effort and money

into developing a potentially game-changing industrial tech- nology: additive manufacturing.”

We learned first-hand of the role metal AM might play in terms of fleet readiness and logistics during a recent discussion with John Murray, president of Concept Laser, Inc., and Rey Chu, principal, manufacturing technologies, PADT, Inc. Concept Laser and PADT recently joined forces to help prove-out the application of 3D metal printing to restore aging aircraft-engine parts.

Warbird’s Exhaust Stack Better Than New

Specifically, Concept Laser and PADT worked together to

32 | 3D METAL PRINTING • SPRING 2017

3DMPmag.com

3D FEATURE