Page 20 - 3D Metal Printing Spring 2017

P. 20

3D FEATURE Caterpillar’s

Grand AM Plan

...includes building the infrastructure to ensure that 3D printing nourishes the company’s engineering teams as it strives to continually innovate.

The Caterpillar hub-and-spoke AM model features a newly minted inhouse AM factory, supported by a service-bureau network that’s

moving AM ideas from the design suite into production.

BY BRAD F. KUVIN, EDITORIAL DIRECTOR

Caterpillar employs more than 10,000 engineers, and, according to addi- tive manufacturing (AM) product manager Stacey DelVecchio, “it’s critical that AM becomes an integral part of the design systems that

our engineers use. AM must become part of their toolset, and we’re hard at work building the infrastructure to make that

happen.”

One of the challenges facing DelVecchio, who has

been directing Caterpillar’s AM factory since its incep- tion early in 2015: How can her team encourage

Caterpillar designers to consider AM?

“This is a big culture challenge that we’re work-

ing on,” she says. “We want our engineers to be creative and innovative, yet we do not require them to use AM. We want them to learn all about the capabilities AM provides, and consider it as they

design new parts and assemblies.”

Toward that end, her team of 10 in the AM factory

have sponsored AM summits, sharing their knowledge and success stories with the company’s engineers. With a rich history in using stereolithography, via an inhouse rapid-pro- totyping lab launched in 1991, Caterpillar leadership decided to

up its AM game in 2014.

“That’s when the technology reached a point where we believed we

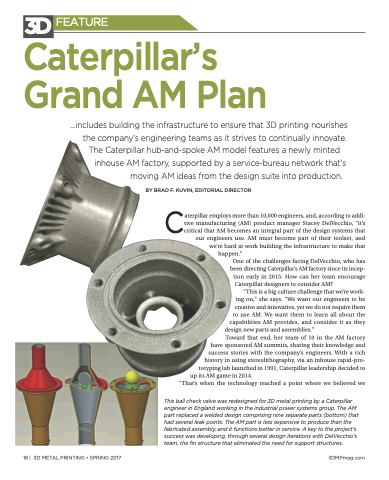

This ball check valve was redesigned for 3D metal printing by a Caterpillar engineer in England working in the industrial power systems group. The AM part replaced a welded design comprising nine separate parts (bottom) that had several leak points. The AM part is less expensive to produce than the fabricated assembly, and it functions better in service. A key to the project’s success was developing, through several design iterations with DelVecchio’s team, the fin structure that eliminated the need for support structures.

18 | 3D METAL PRINTING • SPRING 2017

3DMPmag.com